OUR STRENGTH

Purchase of raw materials

Health and safety are a must for us. Whether natural or synthetic fibers, we only buy raw materials that meet certified qualitative and toxicological standards. The selection of a hyper-qualified supply chain is crucial to the success of this phase, as the fibers must meet extremely high-quality standards.

Dyeing

The first step of this process is the dyeing of the fibers. First, the material is sent to the dye shop, where the color is initially developed through testing and then sampled in the laboratory.

Next, the material is transferred into the plates of the various dyeing tanks. During this process, we repeatedly check the accuracy of the required color and hue. Finally, the material obtained is centrifuged and dried in a hot air oven.

Preparation of the blend

All the elements in the “blend” are made from a sample produced by a machine called Cardina, which reproduces a mini version of the combination of fibers and colors. Once the hue is right, we prepare the blend in large quantities and then send it to the internal carding department. Having an internal carding service allows us to speed up the process and optimize the quality of the final product.

Carding

The elements in the blend are first teased and then mixed with oil and an antistatic product, according to the material being processed. The result is subsequently sent to the carding machines, which produce the carded tape (in bumps), in different weights.

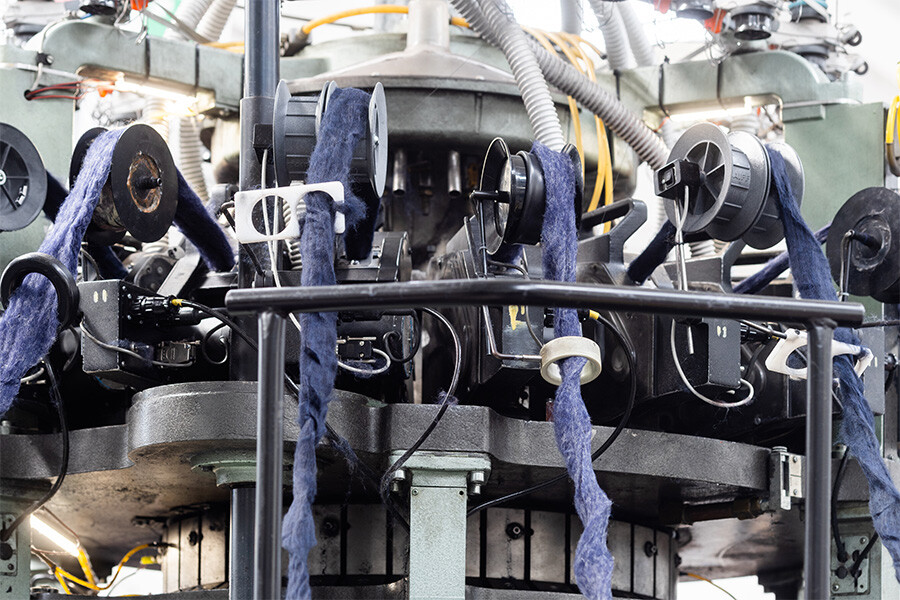

Sliver knitting

The material obtained from the carding is then used for the sliver knitting, together with a textured polyester binding thread, usually recycled, to make the knitted fabric. We also use silk as yarn for the base. Knitting can be different according to the various aspects we want to obtain, such as furs and sherpas or boiled wool. All can be created both solid or jacquards, using in this case Wildman-Mayer machines.

We have over 45 sliver knitting machines at disposal. This helps us increase our production capacity and guarantee fast deliveries.

Finishing

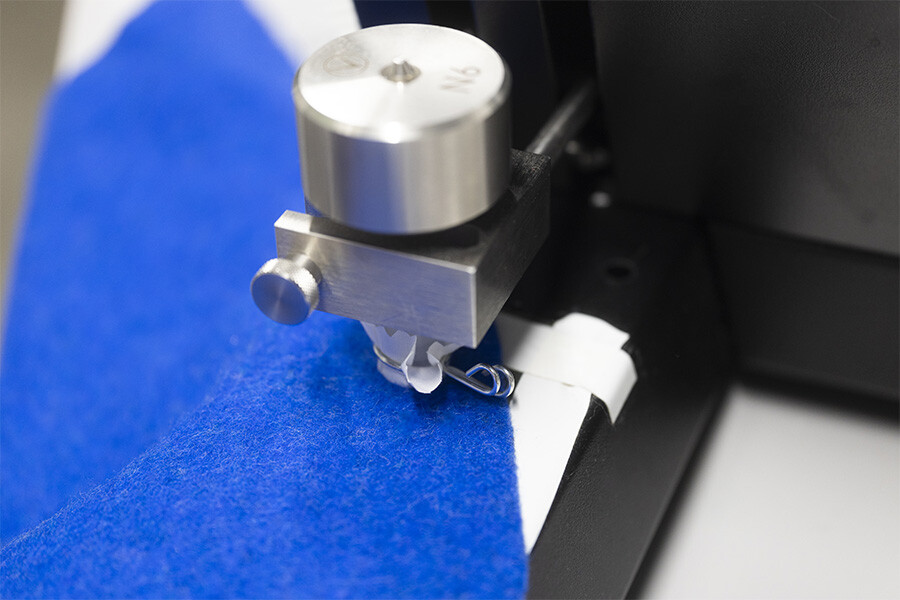

During this enhancing process, the fabric is trimmed, sewn and sent to the various processing stages, depending on the desired finish. There are various washing procedures: dry-milling, tumbler drying, polishing, needling and many more, which give the knitted article the desired characteristics.

Quality control and testing laboratory

The process begins and ends with strict quality, chemical and physical tests. Our technicians begin by checking the structure of the fabric for any imperfections. In the internal testing laboratory (or in the best laboratories in the district), we test the fabric throughout the production to establish its weight and composition, as well as its color resistance and correct washing. Our fabrics have to meet a set of essential technical standards to respect the needs of our customers, therefore, when they are loaded onto the trucks for shipment, we are certain they are exactly as ordered and expected by our clients.

Logistics and shipments

Delivering on time is no less important than producing high-quality fabrics. At Furpile Idea, having efficient and well-organized processes means also guaranteeing correct and timely deliveries. Luckily, we can also count on our well-stocked warehouse in Prato, which often helps us ensure short delivery times.

Keep in touch

Contact us for more information or to receive a fabric sample.